In engineering, understanding how things move and how to control that motion is essential. Dynamics and control systems form the backbone of disciplines ranging from robotics and automated manufacturing to vehicle stability systems and aerospace navigation. Together, they enable engineers to predict, optimise, and regulate motion, ensuring machines and systems work safely, efficiently, and precisely.

What is Dynamics?

Dynamics is a branch of mechanics that examines the motion of bodies and the forces that cause or influence that motion. It extends the principles of kinematics—which focuses on describing motion—to also account for the physical reasons behind movement.

In engineering contexts, dynamics can be divided into:

- Particle dynamics – where the object’s size and shape are negligible compared to its path of motion.

- Rigid body dynamics – where objects are treated as solid bodies with fixed shapes, ignoring deformations.

- Fluid dynamics – where the flow and motion of liquids and gases are studied.

Understanding dynamics allows engineers to:

- Predict the trajectories of moving parts.

- Analyse vibration in mechanical systems.

- Design systems that can handle dynamic loads without failure (Hibbeler, 2017).

For example, in automotive engineering, dynamics is used to study how suspension systems respond to road irregularities, ensuring a smooth ride while maintaining safety.

What are Control Systems?

A control system is a set of devices and algorithms designed to regulate the behaviour of machines or processes. Its purpose is to make a system’s output follow a desired response, even in the presence of disturbances.

Control systems are broadly classified into:

- Open-loop control systems – where actions are taken without feedback, relying on predefined instructions.

- Closed-loop (feedback) control systems – where real-time data is fed back into the system to correct performance deviations.

Control engineering integrates sensors, actuators, and controllers to maintain stability, accuracy, and efficiency. According to Ogata (2010), the essence of control systems lies in feedback mechanisms, which compare actual performance with the desired target and make automatic adjustments.

Dynamics and Control: Working Together

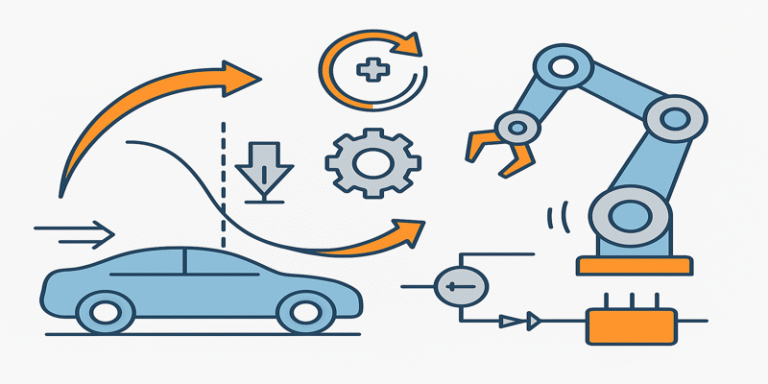

In modern engineering, dynamics and control are inseparable. Dynamics tells us how a system behaves naturally, while control systems tell us how to make it behave as we want.

For example:

- In robotics, dynamics models predict how a robotic arm will move under applied forces, while control systems ensure it follows the precise path required for assembly.

- In autonomous vehicles, vehicle dynamics predict how steering, acceleration, and braking affect movement, while control algorithms ensure safe navigation in real-time.

- In aerospace engineering, the dynamic model of an aircraft predicts its motion under aerodynamic forces, while autopilot systems control its trajectory.

Core Concepts in Dynamics

1.0 Newton’s Laws of Motion

Dynamics relies heavily on Newton’s three laws:

- An object remains at rest or in uniform motion unless acted upon by an external force.

- Force equals mass times acceleration (F = ma).

- For every action, there is an equal and opposite reaction.

These laws provide the mathematical framework for predicting motion in most mechanical systems.

2.0 Energy and Momentum Principles

The work-energy principle relates the work done by forces to the change in kinetic energy, while momentum principles describe how motion is affected by impulse forces. These principles are particularly important for impact analysis in machinery and vehicles.

3.0 Vibration Analysis

Many engineering systems experience vibration—oscillatory motion caused by imbalances, shocks, or resonance. Dynamics provides tools to predict and minimise unwanted vibrations, which can damage components or reduce efficiency (Rao, 2017).

Core Concepts in Control Systems

1.0 Feedback Mechanisms

Feedback compares the actual output of a system with the desired output and adjusts inputs to correct errors. This is fundamental to stable and accurate performance.

2.0 PID Control

One of the most widely used control strategies is Proportional-Integral-Derivative (PID) control. It adjusts system inputs based on:

- Proportional term: response to current error.

- Integral term: correction for accumulated past error.

- Derivative term: anticipation of future error trends (Nise, 2019).

3.0 System Modelling and Transfer Functions

To design effective controllers, engineers create mathematical models—often in the form of transfer functions—that describe how inputs are transformed into outputs. This allows them to predict system behaviour under different control strategies.

Applications of Dynamics and Control Systems

1.0 Robotics

Industrial robots depend on dynamic models for movement prediction and control algorithms for precision. High-speed assembly lines use feedback systems to ensure that robotic arms operate within micrometre-level tolerances.

2.0 Vehicle Stability and Safety

Modern vehicles use Electronic Stability Control (ESC) systems, which monitor steering and wheel speed sensors. The control system compares the driver’s intended path with the actual vehicle trajectory, applying selective braking to prevent skidding.

3.0 Aerospace Navigation

Aircraft autopilot systems integrate flight dynamics with advanced control algorithms to maintain altitude, heading, and speed under varying weather conditions and turbulence.

4.0 Automated Manufacturing

CNC (Computer Numerical Control) machines rely on dynamic modelling for cutting forces and vibrations, while control systems ensure precise tool paths for machining complex shapes.

5.0 Renewable Energy Systems

In wind turbines, control systems regulate blade pitch and generator torque to optimise energy capture while minimising structural loads predicted by dynamic analysis.

Emerging Trends and Technologies

The integration of artificial intelligence (AI) and machine learning into dynamics and control systems is enabling self-optimising machines. These systems can adapt to changing conditions without explicit human intervention, improving efficiency and reliability.

Digital twins—virtual replicas of physical systems—are also becoming a vital tool. They allow engineers to simulate system dynamics and test control strategies in real-time without risking physical assets (Tao et al., 2019).

In addition, networked control systems are extending control principles to interconnected devices, supporting the growth of the Internet of Things (IoT) in industrial applications.

Challenges in Dynamics and Control Engineering

Despite its successes, the field faces challenges:

- Nonlinear dynamics: Many real-world systems behave unpredictably outside simple linear models.

- Uncertainty and disturbances: External conditions, such as wind gusts or unexpected loads, can degrade performance.

- System complexity: As systems become more interconnected, ensuring stability and robustness is increasingly difficult.

Research continues into robust control and adaptive control methods to handle these challenges.

Dynamics and control systems underpin much of modern engineering, enabling machines to move efficiently, safely, and precisely. Dynamics provides the foundation for understanding motion, while control systems allow engineers to regulate and optimise it. Together, they drive innovation in robotics, manufacturing, transportation, energy systems, and beyond.

As technology evolves—with advances in AI, digital twins, and IoT—the integration of dynamic analysis and sophisticated control strategies will remain central to engineering progress. The future promises systems that not only operate at peak performance but can also adapt intelligently to a changing world.

References

Hibbeler, R. C. (2017). Engineering Mechanics: Dynamics (14th ed.). Pearson.

Nise, N. S. (2019). Control Systems Engineering (8th ed.). Wiley.

Ogata, K. (2010). Modern Control Engineering (5th ed.). Pearson.

Rao, S. S. (2017). Mechanical Vibrations (6th ed.). Pearson.

Tao, F., Zhang, H., Liu, A. & Nee, A. Y. C. (2019). “Digital Twin in Industry: State-of-the-Art.” Robotics and Computer-Integrated Manufacturing, 61, pp. 101–108.